How to avoid staining when using fugitive adhesives?

This is a question we are asked often.

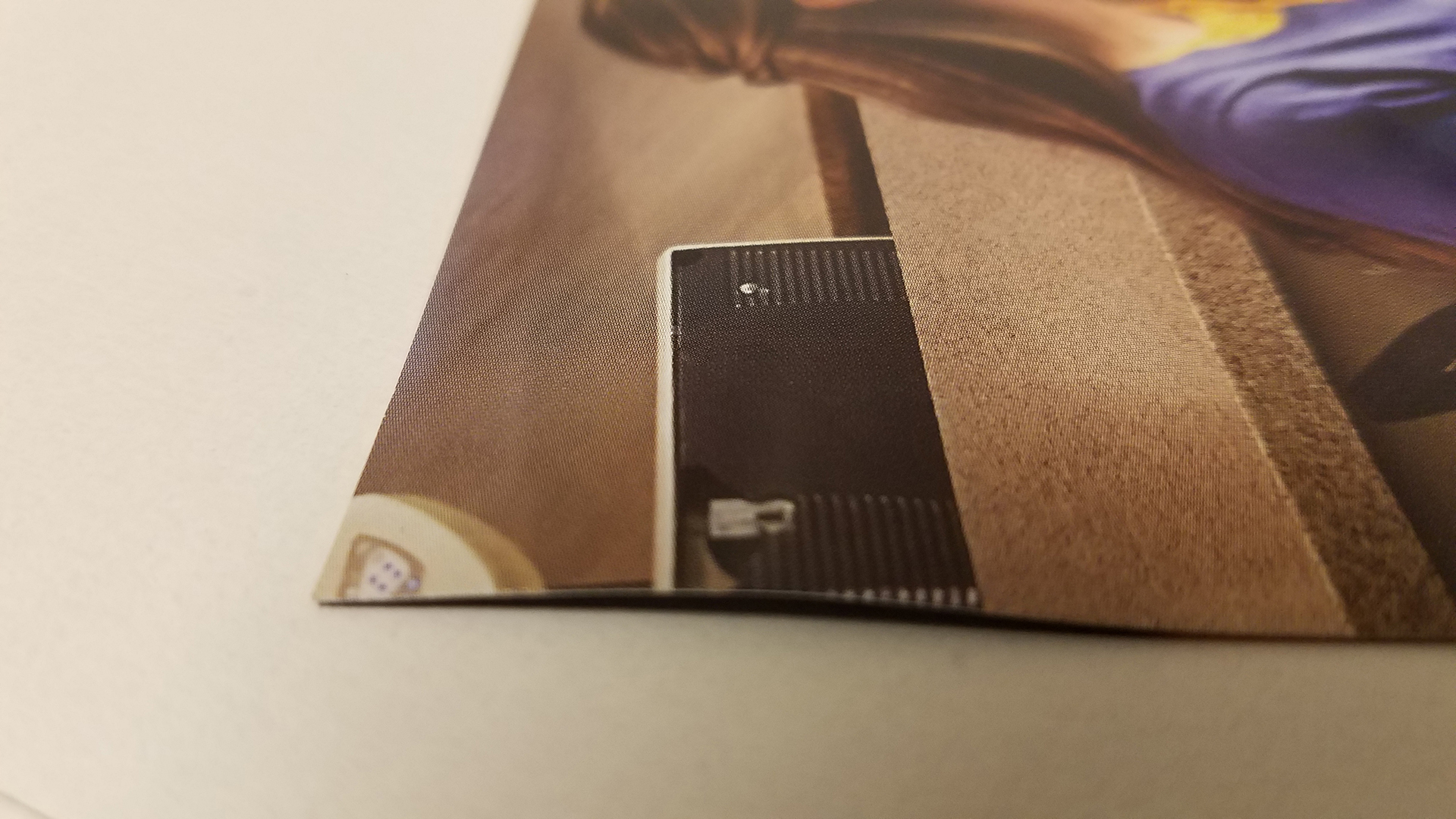

An important thing to remember is that not all fugitive adhesives, paper stock, print inks, and overprint coatings are the same. Finding a balance between good fugitive glue adhesion and stain-resistance has been a challenge we’ve seen in the direct mail industry for years.

Since glue staining is inherently a result of the number of releasing agents in the fugitive hot melt adhesive used to reduce tack, it’s very important to have a coating that provides a barrier to protect the mailer long term. Our CA14705 coating was specifically designed with longevity in mind, offering superior fugitive hot melt stain protection for glued mailers.

Try our CA14705 stain-resistant coating on your next fugitive mail project to minimize downtime and reduced waste.

Designed to provide enhanced resistance to fugitive hot melt staining, industrial chemicals, extreme temperatures, scuffing abrasion, water, and friction, the Capital Adhesives CA14705 aqueous coating provides converters and brand owners a solution to waste overages and returned job runs due to stains from fugitive adhesives.

Uncoated Mailer

Coated Mailer

Additional Information

- Stain-resistant coating for use on direct mailers where fugitive hot melt adhesives are used.

- Equipment Application: Flexo, Gravure, Direct Roll Coat, Enclosed Dr Blade

CA14705 Benefits

- Use On Any Paper, Saving Money

- Eliminate Customer Staining Complaints

- Reduce Hot Melt Product SKU’s

- Increase Line Speeds

The CA14705 is a perfect pairing for the Capital Adhesives Hot Melt Fugitive Adhesive lineup.

Speak with a solutions expert today to discover which pair of coating and hot melt fugitive products will work best for your application.