Litho lamination is the joining or nipping together of two substrates such as a printed litho sheet/label and corrugated board using adhesives. Once the adhesive is cured, bond strength is generally high enough to cause failure or tearing of the porous substrate. Litho lamination is commonly used as a cost-saving solution in the manufacturing of custom retail packaging and point-of-purchase displays.

A challenge that many convertors have to overcome in the litho lamination process is called “tunneling”.

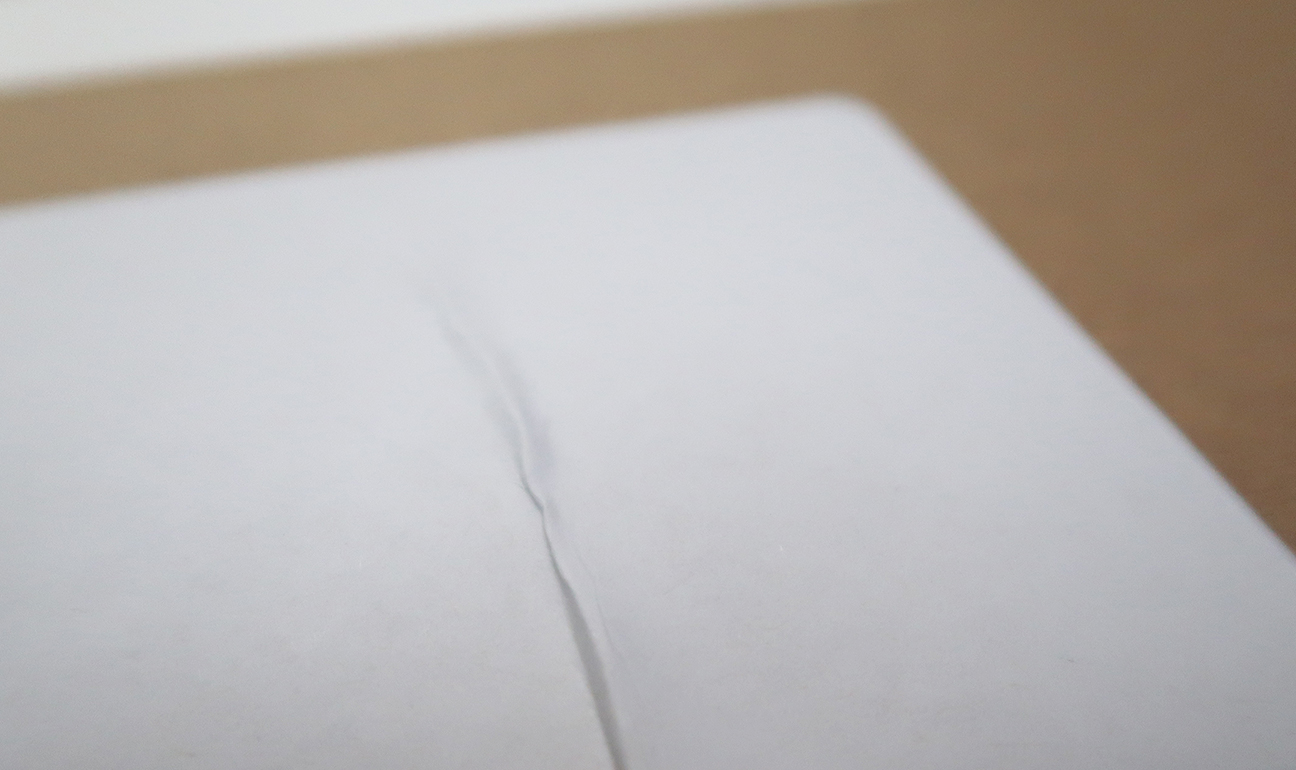

Example of Tunneling

Tunneling is the localized separating or delamination of the substrates often caused by differences in moisture content in the substrates. When tunneling occurs it can have a detrimental effect on the laminate’s appearance and performance.

Capital Adhesives has developed a unique line of litho lamination adhesive products to help reduce issues like tunneling all the while maximizing efficiencies. Contact our experienced team and partner with us to solve these and other challenges.

Ready to discuss your application?